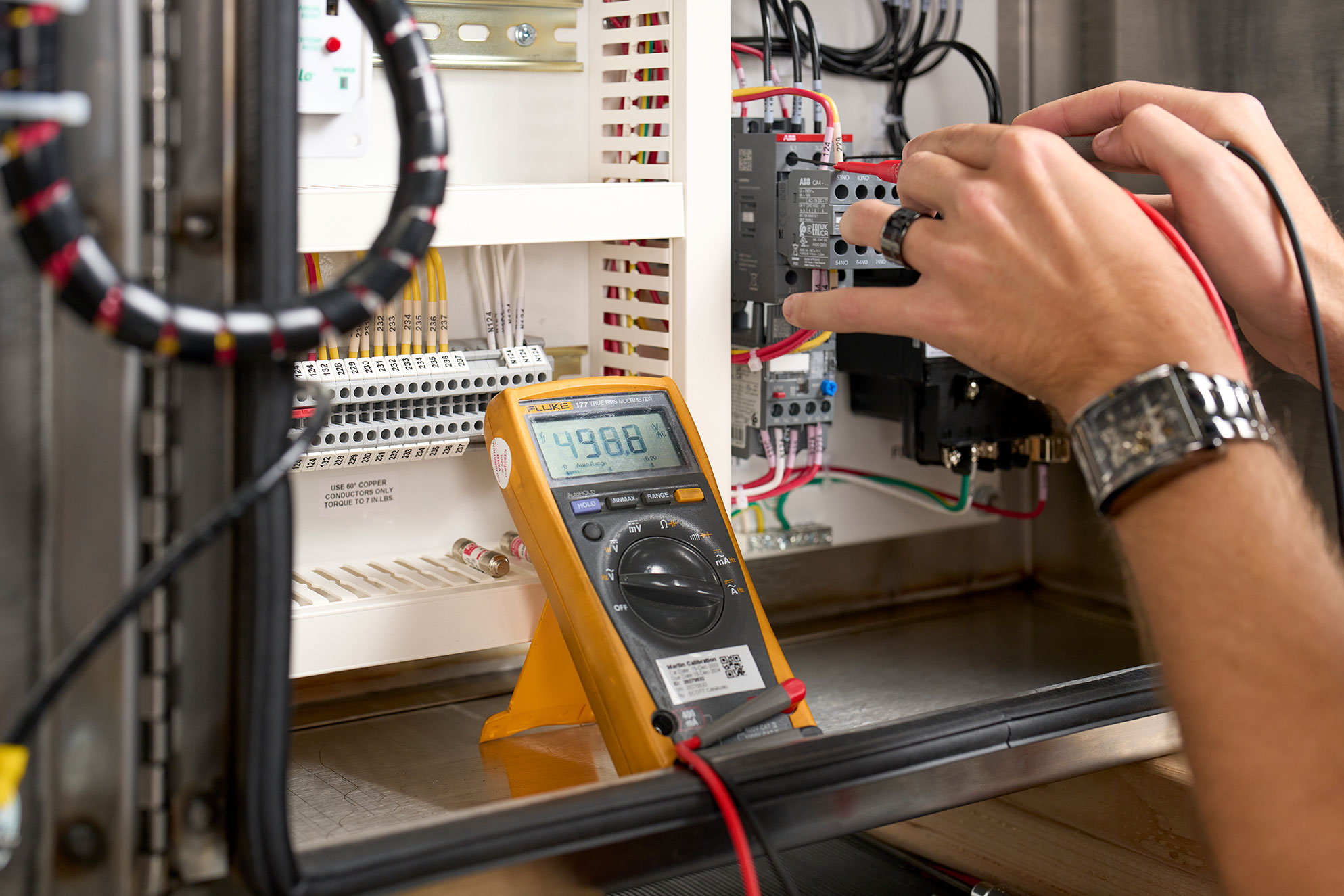

Precision and Quality

Each assembled and wired panel undergoes a detailed checkout procedure that is developed specifically for its application. Each job, once completed, is documented procedurally and with photos, for any quality defects; which is then retained digitally for our customers and TPC own internal improvement process.

In-Depth Testing Process

Our meticulous control panel and system checkout procedures encompass a wide range of critical tests and verifications, including but not limited to:

- Verification that the correct components are properly installed, wired (and plumbed -where applicable)

- Panel “power-up” and powered check out procedure

- Point-to-point continuity testing

- I/O simulation or functional testing if software is required and supplied

- Operator Interface functionality & verification

- Terminal torque testing

- Nameplate, labeling, and wire numbering verification

- Instrument set-up and calibration

- Testing as required to confirm complete system functionality in accordance with the project requirements

- FAT & SAT upon request